POPULAR COLOURS

BLACK

BLUE

BRONZE

BROWN

CLEAR

GOLD

GREEN

GREY

ORANGE

PINK

PURPLE

RED

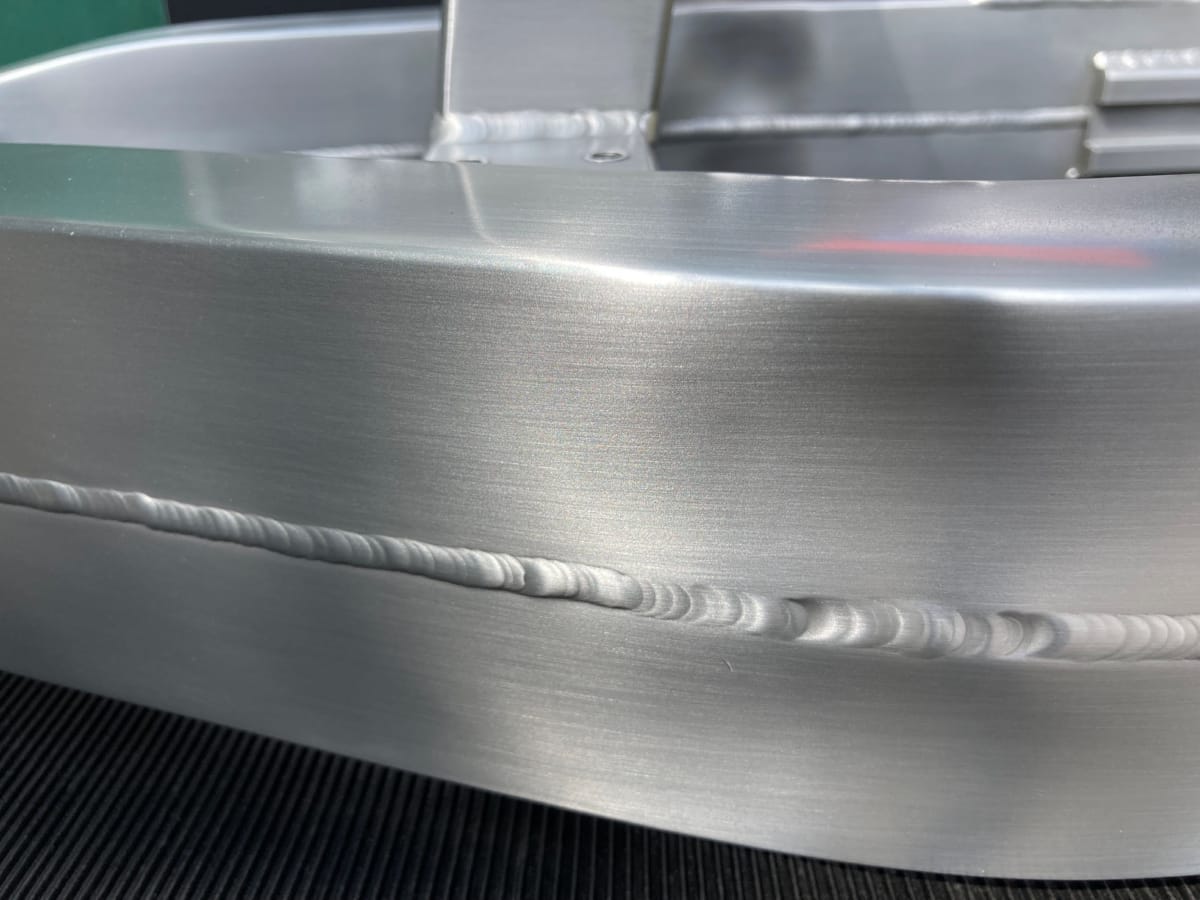

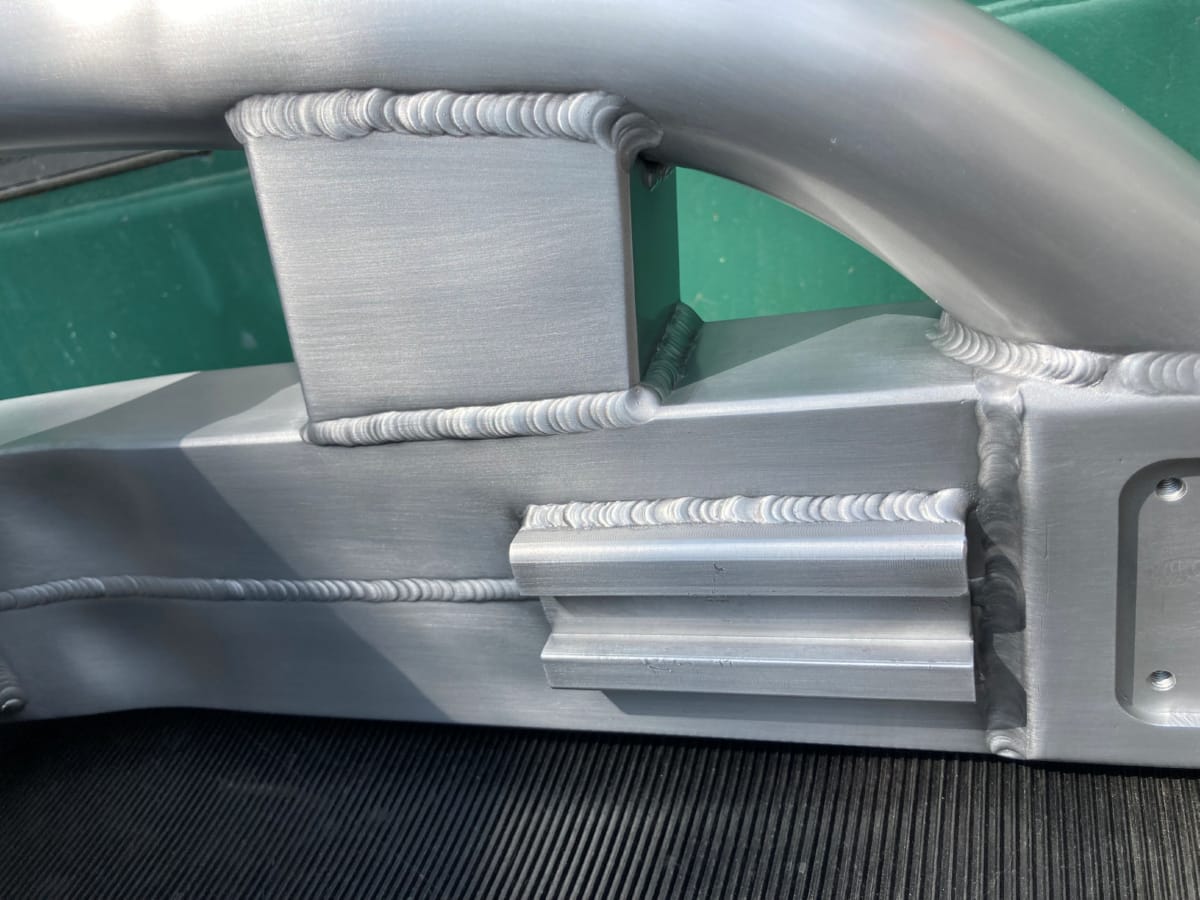

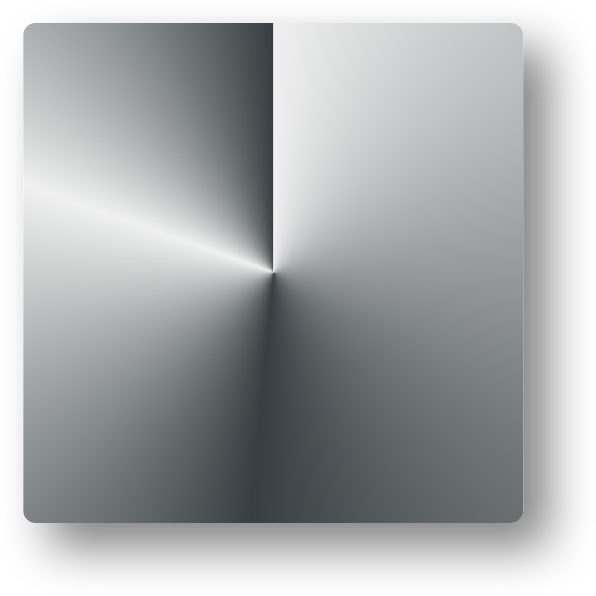

SILVER

TAN

WHITE

YELLOW

G/H/X Grey

G/X Mid Grey

H/X Tobacco

G/X Dark Tobacco

G?H Light Tobacco

G Fawn

G/H/X Cream

H/X Mahogany

G/H/X Black

G Charcoal

G/X Titanium

X Slate Grey